Exploring Embodied Carbon: Insights from My Ongoing Study

- Laura Pachon

- Mar 17, 2025

- 2 min read

Hi, I’m Laura—a Life Cycle Assessment professional and environmental designer with a background in architecture. My passion lies in analysing and testing building materials to assess their environmental impact.

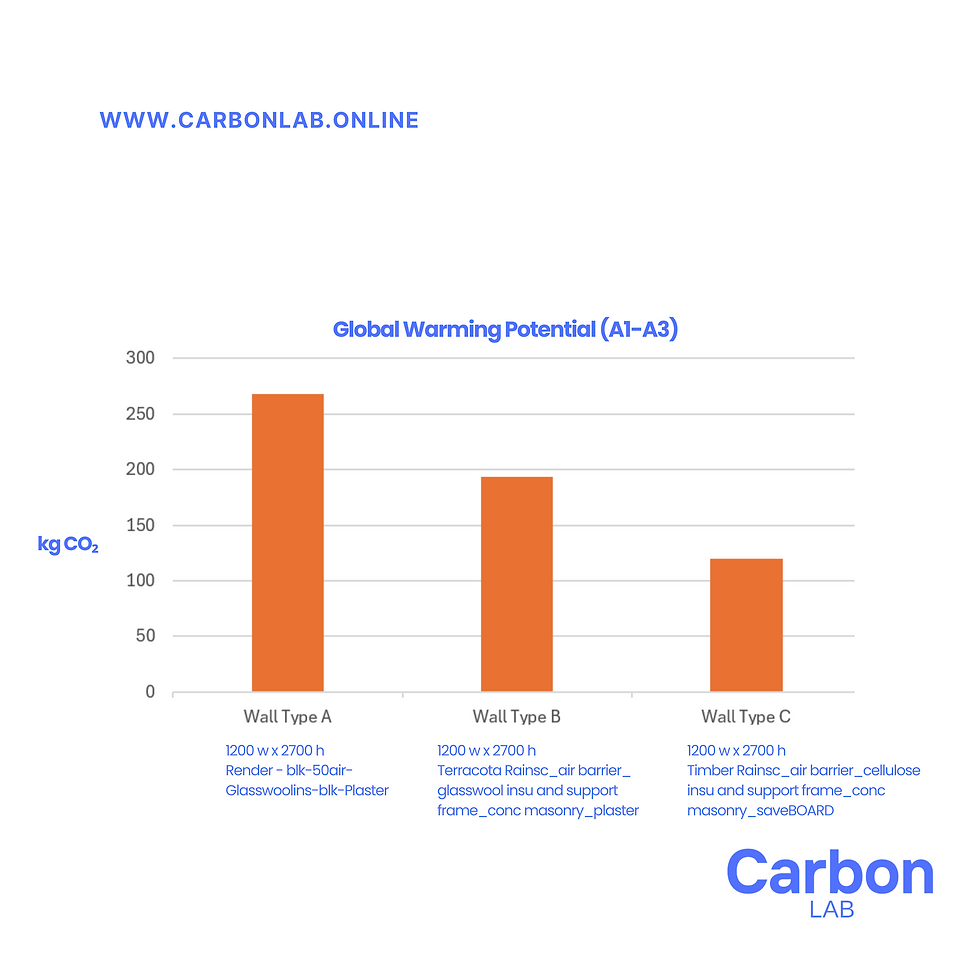

I’d like to share insights from my ongoing embodied carbon study, where I’m developing a wall type library. Using BIM (Revit) and One Click LCA, I’ve tested three key wall assemblies to evaluate their carbon footprint—and more are on the way! The findings have been fascinating.

Wall Types Studied

External Wall Type A: Render - block - 50mm air gap - 30mm glass wool insulation - block - plaster.

Thickness: 314.5mm

R-value: ~2.6 (m².K)/W

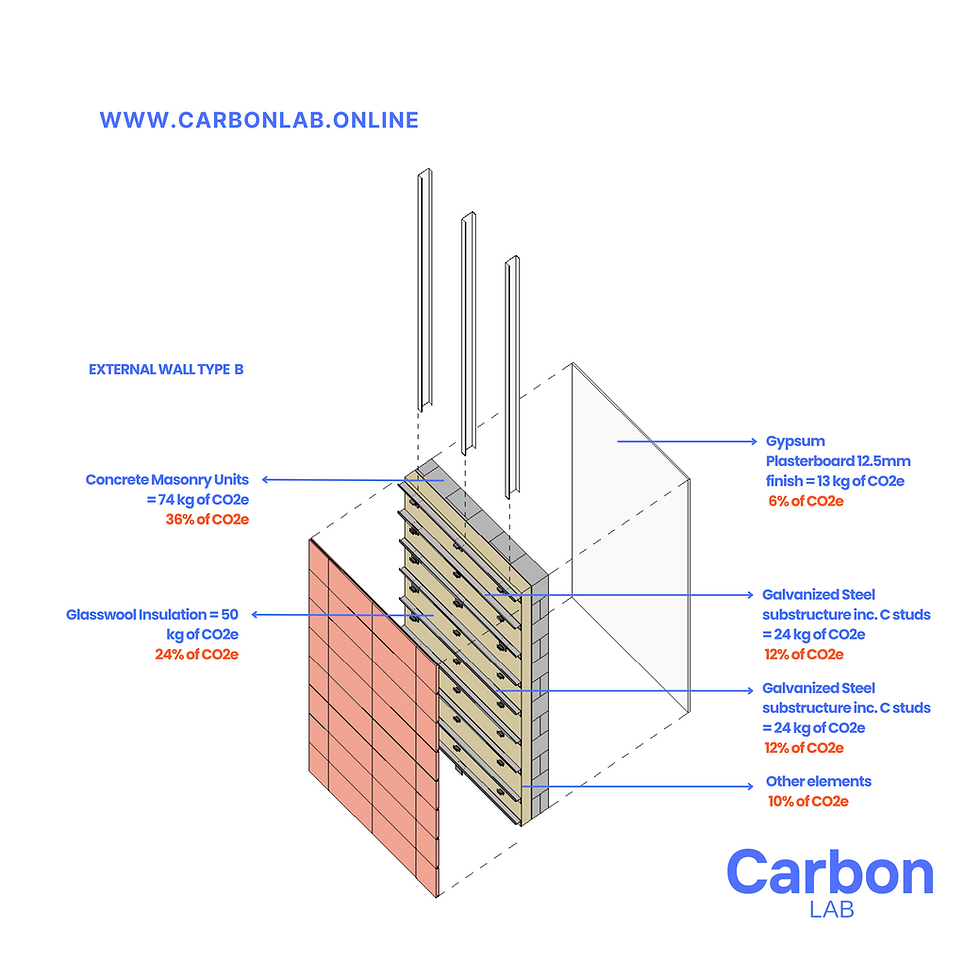

External Wall Type B: Terracotta rainscreen - air barrier - 100mm glass wool insulation + support frame - concrete masonry - 12mm plaster.

Thickness: 322.5mm

R-value: ~6.0 (m².K)/W

External Wall Type C (Improved Version of B): Sustainable timber rainscreen - air barrier - 100mm cellulose insulation + support frame - concrete masonry - saveBOARD.

Thickness: 317.5mm

R-value: ~3.5 (m².K)/W

Key Findings

🚧 Concrete Blocks Have the Highest Embodied Carbon. While concrete blocks provide high thermal mass—absorbing heat during the day and releasing it at night—their embodied carbon footprint is significant. Choosing low-carbon alternatives or optimising material selection (e.g., block filling and sourcing from sustainable manufacturers) is critical.

💡 Insulation Makes a Huge Difference!

Glass wool insulation (Wall Type B): 50 kg CO₂

Cellulose insulation (Wall Type C): Only 5 kg CO₂ 🌿 (That’s a 90% reduction!)

Cellulose, made from recycled paper, has a lower embodied carbon footprint. However, it’s important to note that cellulose has a lower R-value than glasswool, affecting overall thermal performance.

⚠️ Don’t Ignore the Cladding Substructure! In rainscreen facades, the substructure alone accounted for ~12% of total emissions in Wall Type B. It's important to consult with your facades specialist and material provider to review most efficient design.

✅ Optimized Material Selection = Lower Carbon Footprint

By switching from:

Glass wool → Cellulose insulation

Plasterboard → saveBOARD

Clay tiles → Timber tiles

Wall Type C cut its total embodied carbon by 148 kg CO₂!

Balancing Embodied Carbon & Thermal Performance

While reducing embodied carbon is essential, it’s equally important to consider R-value (A material’s ability to resist heat flow) optimisation for thermal comfort and energy efficiency. In Sydney’s warm temperate climate (mild winters, warm summers), the ideal R-value depends on building type and compliance with the National Construction Code (NCC) and type of accreditation you're trying to follow for example (Passive House). Generally speaking the Higher R-values reduce heating and cooling costs. Condensations risks play a big role in Sydney needing well-insulated homes with proper vapour barriers and ventilation systems is also essential in the mix.

This study reinforces the importance of smart material selection—not just for carbon savings but for better energy efficiency. Stay tuned as I continue to expand the wall type library and explore more sustainable building solutions!

Comments